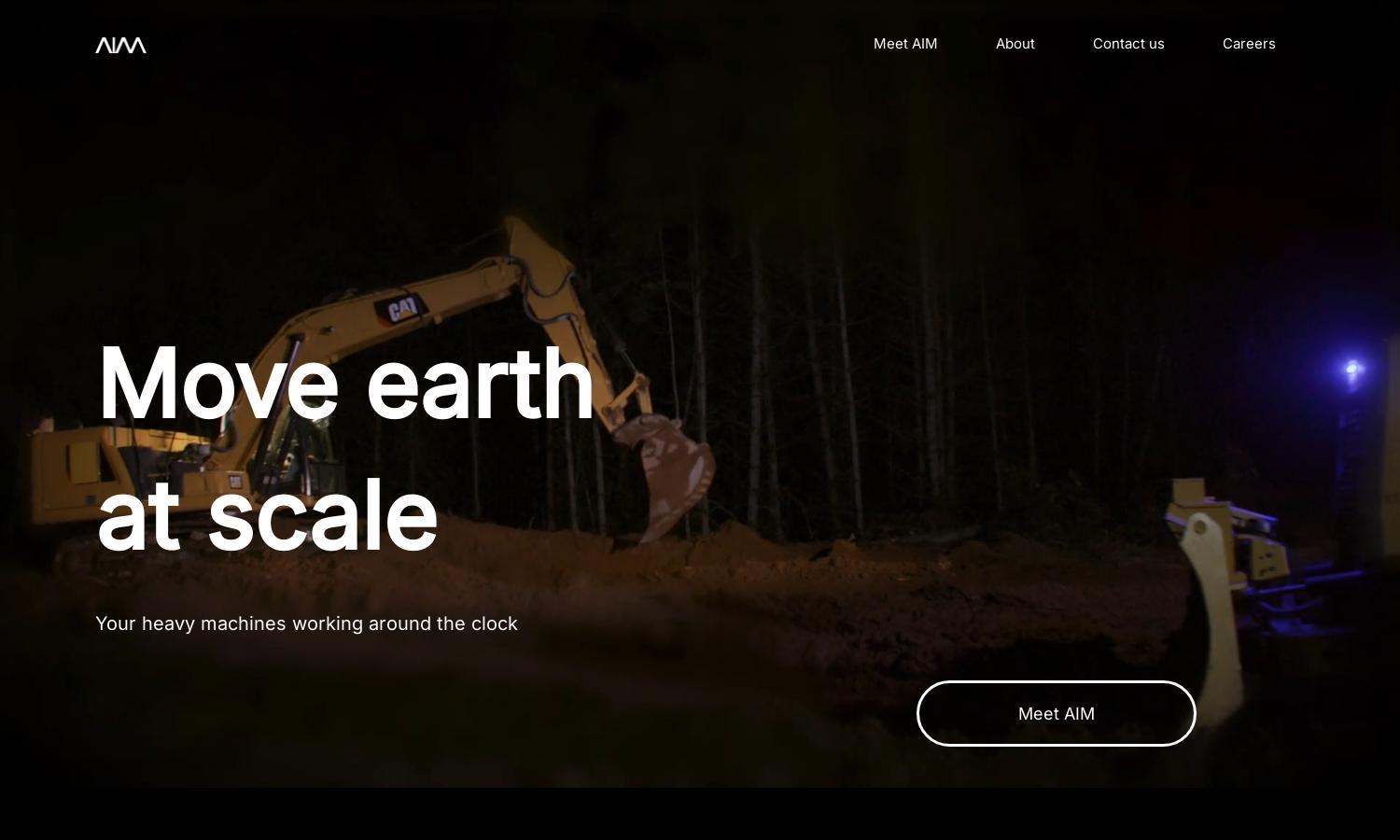

AIM Intelligent Machines

About AIM Intelligent Machines

AIM Intelligent Machines revolutionizes heavy equipment with autonomous technology for enhanced safety and productivity. Targeting industries like construction and mining, AIM retrofits existing machinery for seamless, accident-free operation. Users benefit from increased efficiency, continuous operation, and safety enhancements, enabling advanced skills and better resource management.

AIM Intelligent Machines offers consultation services on autonomous machinery, tailoring solutions based on user needs. The flexible pricing model provides options for startups and established industries, ensuring value through improved safety and productivity. Upgrading to AIM's systems opens access to advanced features and maximizes equipment utilization.

AIM Intelligent Machines features a user-friendly interface designed for easy navigation and seamless operation. The layout promotes intuitive interactions and efficient access to functionalities and support. Users can quickly adapt to the system, facilitating quick learning and deployment, ensuring safety and productivity in heavy machinery operations.

How AIM Intelligent Machines works

Users start by scheduling a consultation with AIM Intelligent Machines, where they discuss their equipment and needs. During onboarding, AIM evaluates existing machinery and customizes retrofitting solutions. Once equipped, users can easily navigate the automated systems, allowing machines to operate autonomously while maintaining safety features, ensuring optimal performance without operator presence.

Key Features for AIM Intelligent Machines

Fully Autonomous Operation

AIM Intelligent Machines employs fully autonomous operation, transforming traditional heavy equipment into self-operating machines. This key feature allows for continuous, efficient work, significantly reducing the chance of accidents. Users benefit from enhanced productivity, as equipment operates around the clock regardless of weather conditions.

Safety Enhancements

AIM Intelligent Machines prioritizes safety with its multi-layered protection system. This unique feature ensures no workers are exposed to hazardous environments while equipment operates autonomously. Users gain peace of mind knowing their workforce is safe, enhancing overall site safety and boosting productivity without compromise.

Customizable Retrofitting

AIM Intelligent Machines provides customizable retrofitting, allowing any existing machinery to be upgraded for autonomous use. This essential feature maximizes investment by preserving the value of old equipment. Users can adapt their fleets incrementally, benefiting from advanced technology while maintaining manual operation if needed.

You may also like: